When a customer places an order for a product that is on backorder, it means that the product is not immediately available for delivery or pick-up, but the customer is willing to wait until the product becomes available.

In some cases, the product may be manufactured or sourced specifically for the customer, which can result in longer delivery times and additional costs.

Backorders are commonly seen in manufacturing, retail, and e-commerce where it can be challenging to accurately predict demand and ensure that there is sufficient inventory to meet customer needs.

How to calculate backorders

Backorder Quantity = Total Customer Orders – Available Inventory

For example, let’s say you have received 50 customer orders for a product, but you only have 40 units of that product in stock. This means that 10 customer orders cannot be fulfilled immediately and are considered backorders.

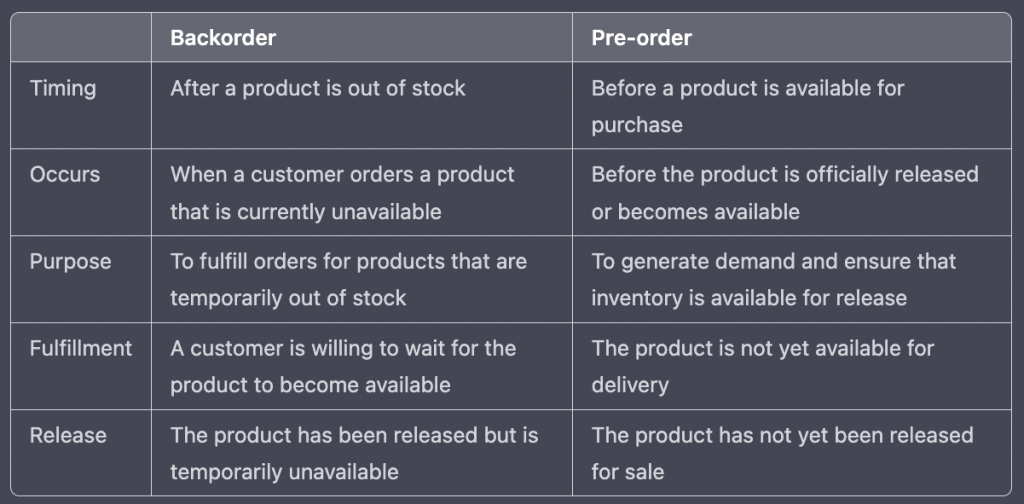

Backorder vs Pre-order

Backorder Analysis

Backorder analysis is used to help understand the impact of backorders. It is used to understand the impact of backorders on inventory, sales, and cash flow.

It can also be used by managers to see how much profit was lost due to backorders or what proportion of customers were satisfied with the service provided because it took longer than expected.

Bottom Line

If you don’t know your backorders, you’re losing money. They are an important part of running a business and a way to manage inventory and customer expectations.

Learn more about finance

No matter your level of financial literacy, we have more than enough financial education resources to get you started. Also, with our wealth management app, you can easily save, invest, and begin your own path to financial independence.

Related Articles:

How To Improve Your Cash Flow – 5 sustainable recommendations